Our mission and challenges

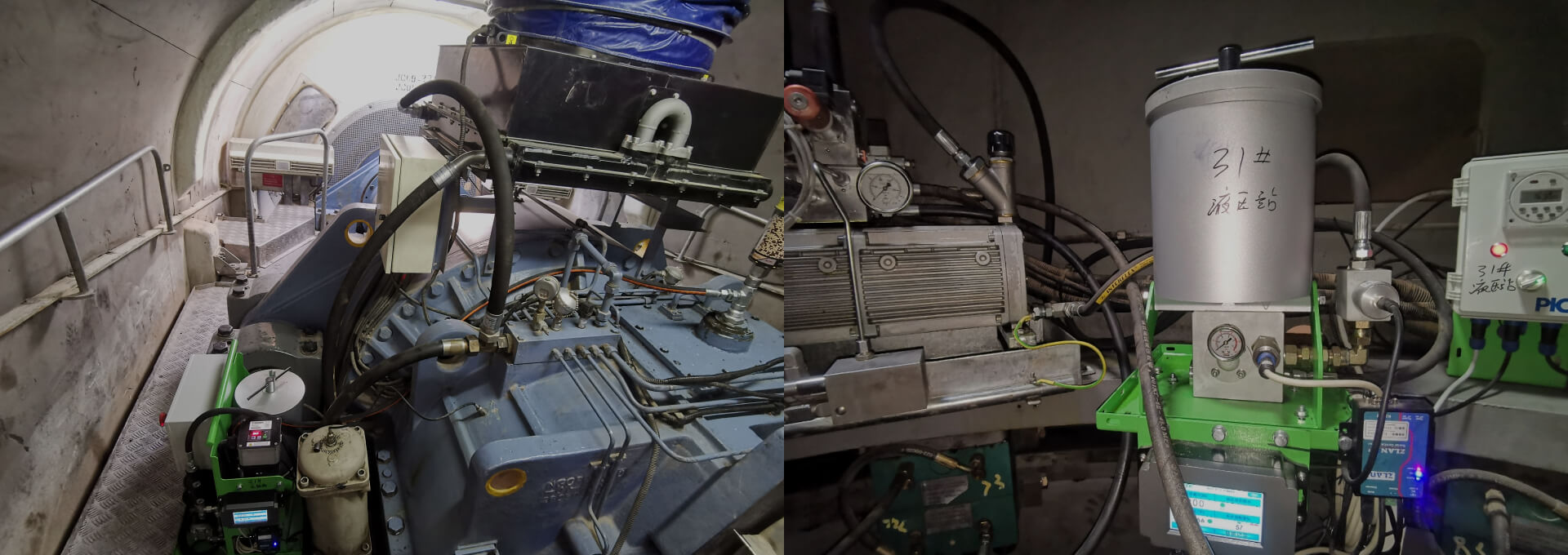

Oil includes hydraulic oil; Gear oil and transformer oil play an important role in the system, just like human blood. According to different research reports, 80% of mechanical failures are related to solid pollution of the oil, and 30% -40% of failures are also caused by water pollution. The existing systems are equipped with online main filters, and the design of the main filter needs to provide sufficient flow to meet the needs of the system to ensure the normal operation of all system components. Therefore, the filtration accuracy range is between 6-35 microns to meet the design requirements. Research has shown that most large particulate pollutants can be filtered out through the main filter, leaving behind 10% of pollutants smaller than 10 microns, while 70% -80% are between 1-5 microns. These small pollutants are the ones that cause the greatest damage to the system. In addition, most main filters cannot filter the water in the oil to achieve the drying effect. Therefore, our company develops our products based on the principle of pollution control technology of ultra-fine filtration. The core of ultra-fine filtration technology research and development is the filter element and filter element. The carrier and the two must work together to achieve the effect of pollution control, The overall design has obtained multiple patent certificates, and the filter element is made of long fiber polypropylene and polyester materials. The design of the filter element is based on the principle of deep filtration, and it undergoes a specially designed three-stage filtration process to achieve high pollution absorption and strong water absorption characteristics. After multiple research and testing, it also achieves pollution control effects after filtering oil with different viscosities

According to a research report from American universities, the annual maintenance cost due to mechanical wear in the United States is 6-8% of the overall Gross Domestic Product (GNP), so maintenance cost is the largest single controllable expenditure. The purpose of oil pollution control can reduce mechanical wear and thus lower maintenance costs to improve profitability. However, in addition to pollution control, oil samples need to be regularly sampled and analyzed to improve the reliability of mechanical operation. Oil laboratory testing also has its drawbacks, which cannot obtain real-time reporting information; Sampling may cause secondary pollution or remote location issues. In addition, according to experience and statistical data, only about 5-10% of the problematic oil in the 100% test report needs to be followed up immediately, and 90% of the test costs are wasted. Therefore, our company also develops real-time online monitoring of the health status of oil quality, and cooperates with intelligent remote transmission technology to achieve the best real-time effect. If there is a change in oil quality, engineers can immediately take oil samples for further analysis to identify the problem or check the operation of the machinery, so as to avoid mechanical failure and delay in maintenance, which will lead to more serious mechanical problems.

Climate change is caused by excessive carbon dioxide emissions, which are attributed to the extensive use of petrochemical raw materials. Our ultra-fine filtration technology combined with oil condition monitoring and intelligent remote transmission technology not only reduces maintenance costs and improves profitability, but also reduces oil usage and recycling, as well as reducing waste oil emissions, to alleviate climate problems.

The above are both our mission and challenges. To achieve our goals, our products and technology are sold worldwide by the following brands.

Applied ultra-fine filtration technologyBenefits and advantages

- 01Removing of all solid contaminants

- 02Removalwaterbyabsorption effectto less than 100ppm

- 03Eliminatingresin and oxidation products

- 04Extend component life

- 05Reduce the cost on full flow filter

- 06Significant reduction ofoilconsumption and oil disposal cost

- 07Environmental benefit

- 08Provide significanteconomic payback

- 09Removing ferrous particle from system and could also diagnostic themachine wear