How to Outsmart Varnish andAvoid Costly Downtime?

What is Varnish?

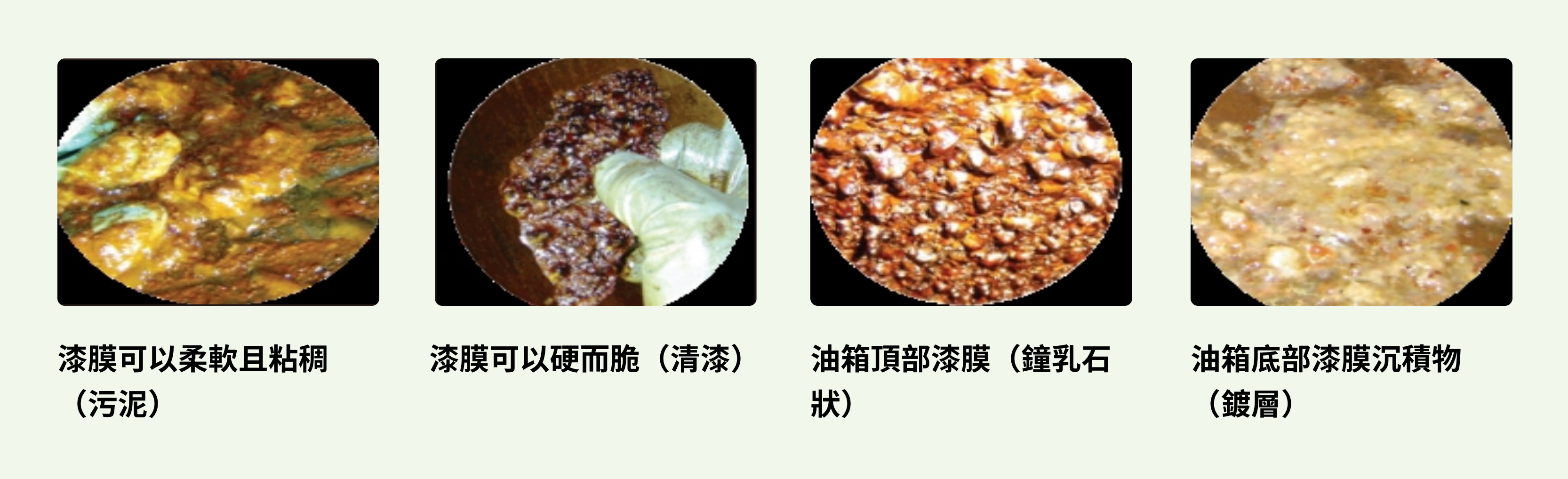

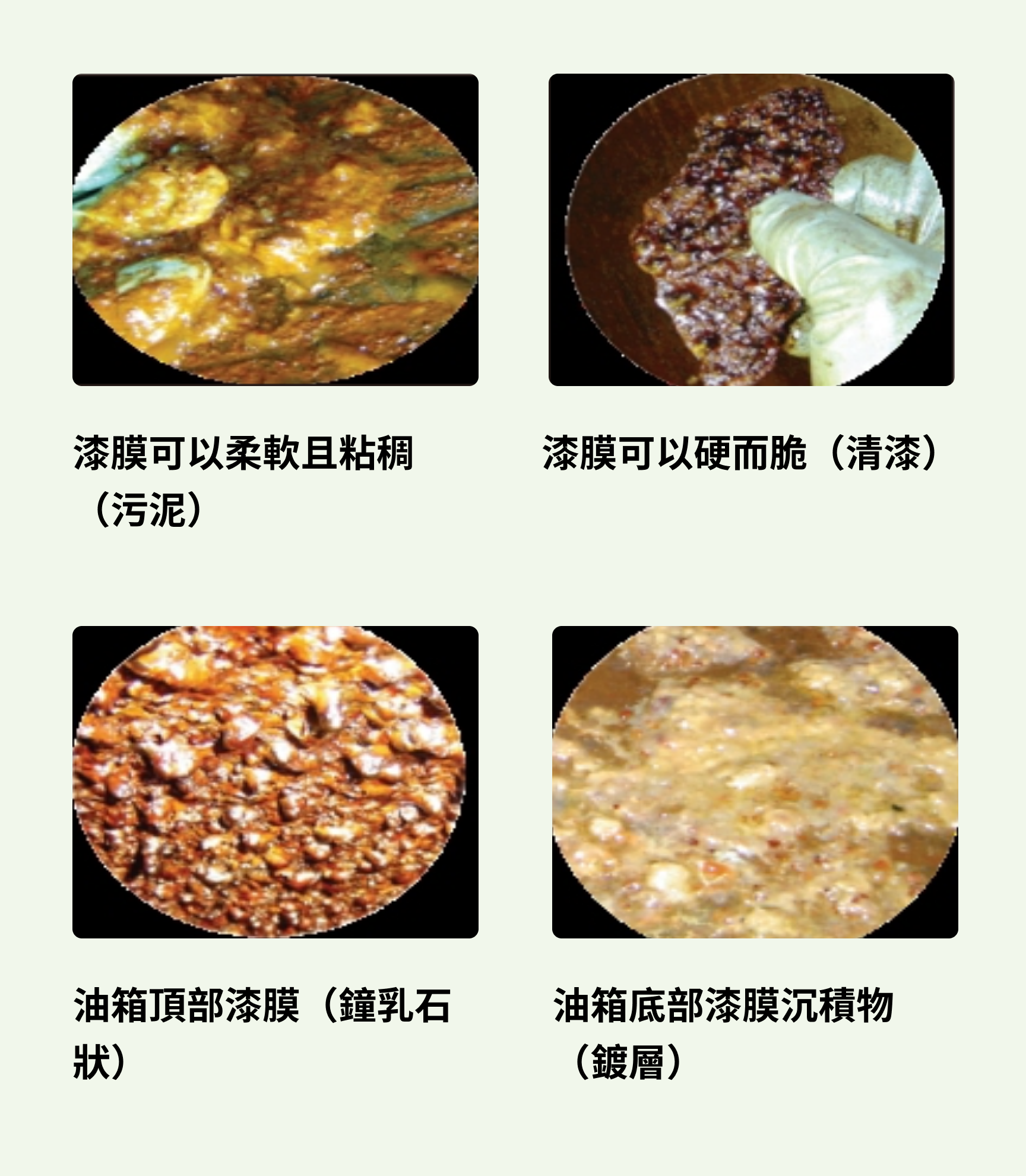

Varnish is a coating that adhere to internal surfaces, wear outequipment components, restricts performance and can ultimatelycause failure. lt is composed primarily of organic residue mixed withmetals, inorganic salts and other contaminants. Varnish can takedifferent forms, from sticky coating to a hard lacquer and ranges incolor from grey to brown to amber. Varnish is very destructive andhard to remove.

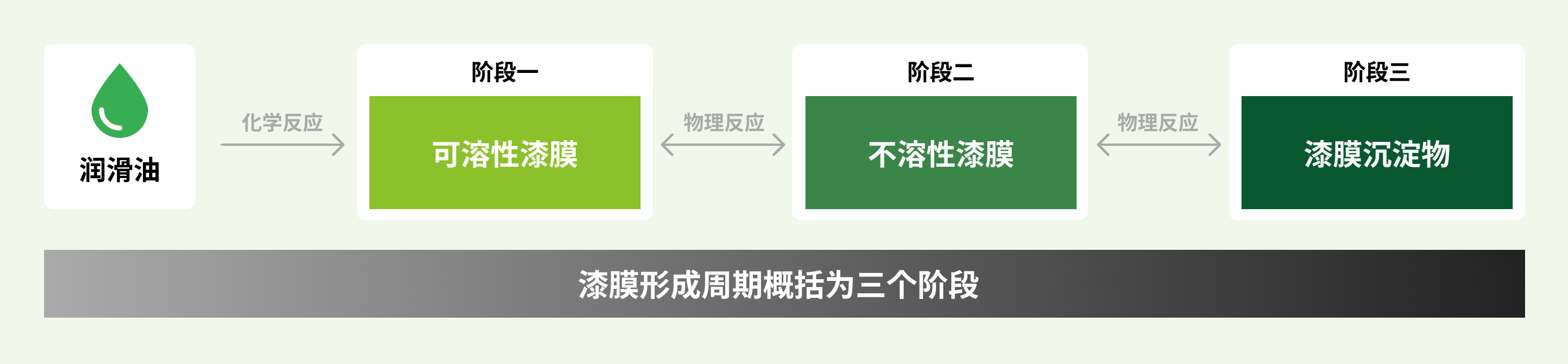

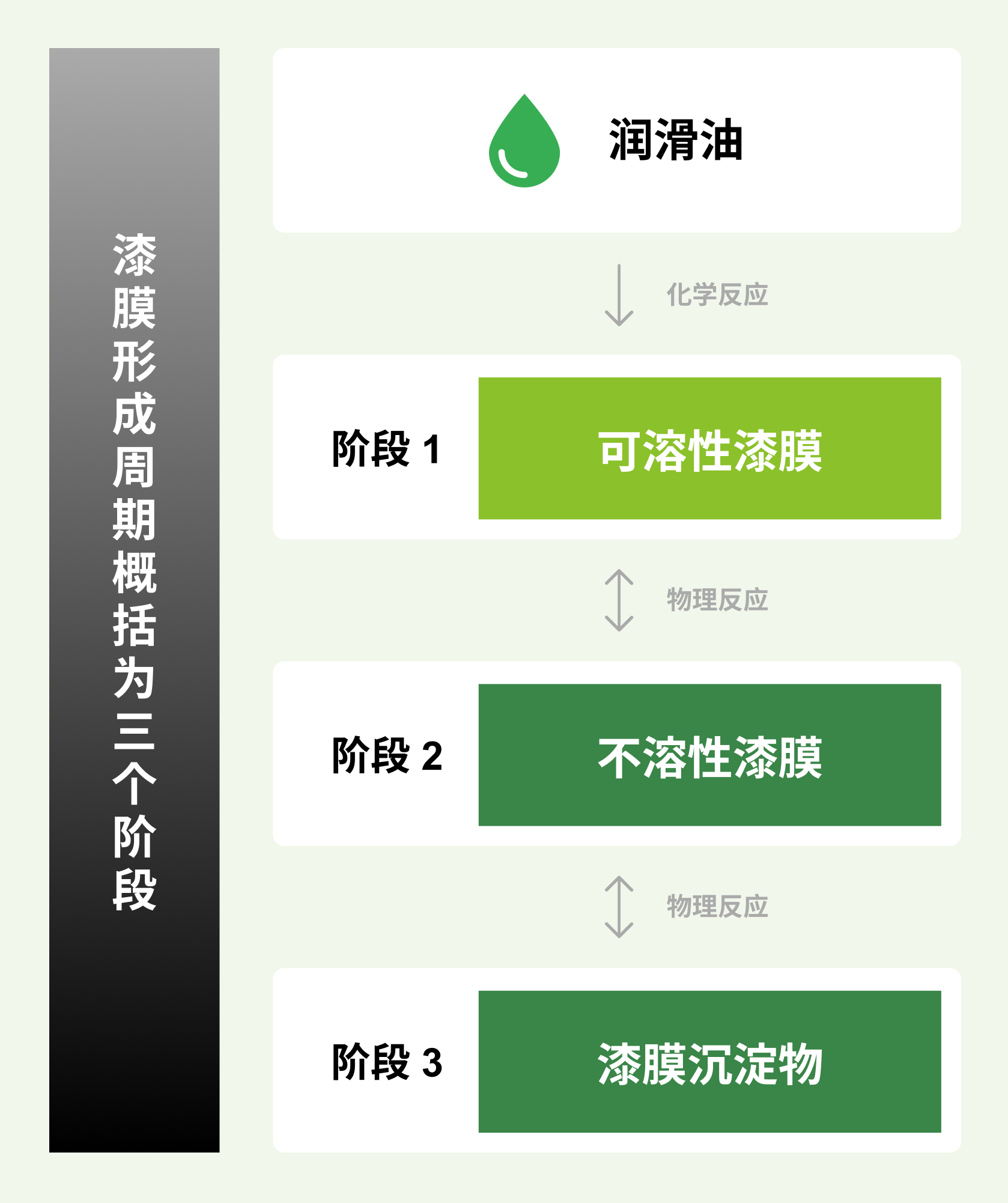

Varnish Formation

Varnish begins its life as a soluble/dissolved degradation products in theprocess of oxidation before converting to particulate form anddepositing on metal surfaces. The typical varnish formation cyclespeciallyin a gas turbine involves the following three steps.

Consequence of Varnish

- Valve sticking-loss ofcontrol, resultingin turbine trips or fail to start.

- Filter blockage- restriction ofoil flow, which increase oil temperature and wear

- Sandpapersurface-increase component wear

- Ineffective heatexchanges-increase oil temperature

- Lacguer baked onto bearing-flow restriction and increased wear and temperature.

- Frequent oil changes and system flushing

TESTING FOR VARNISH

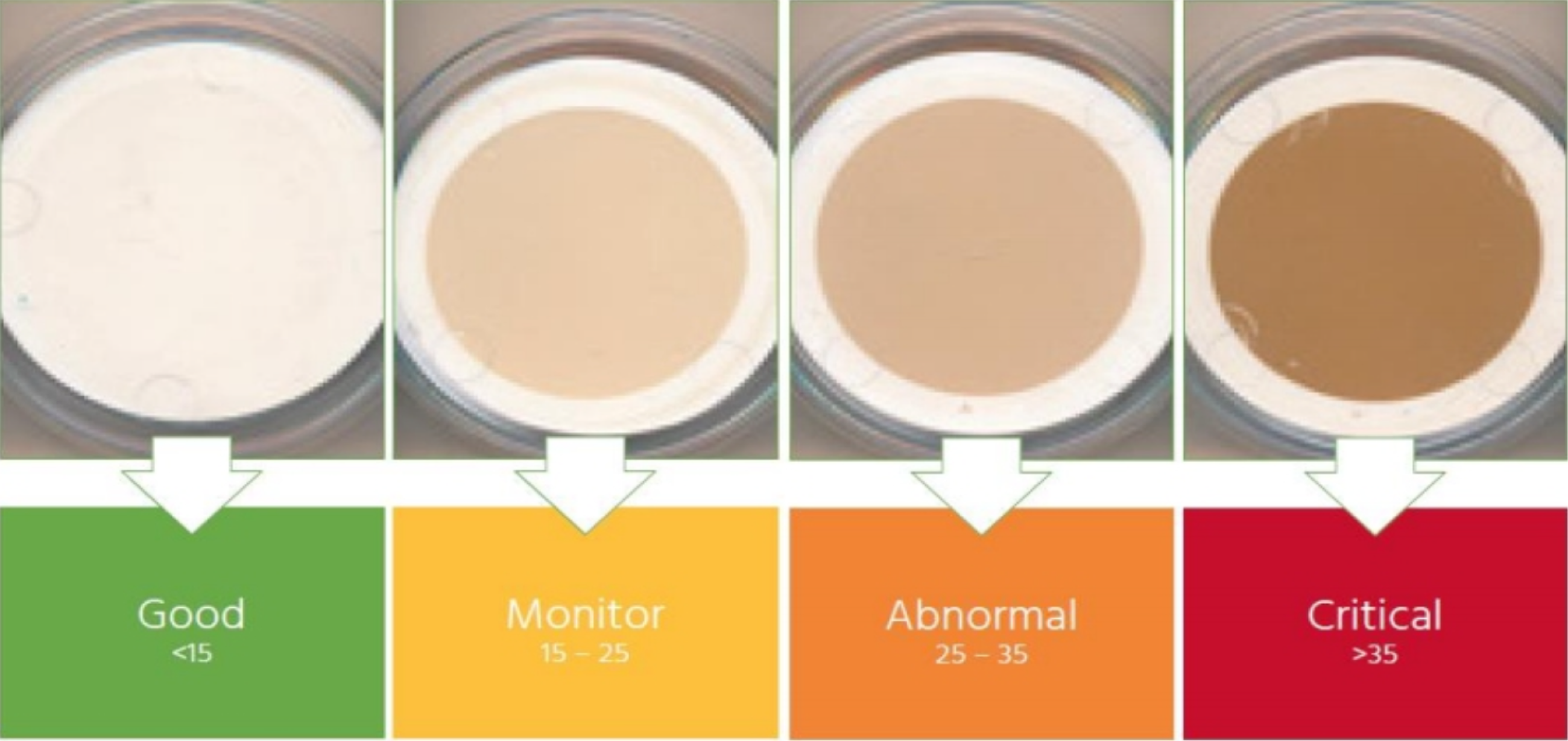

Varnish potentialtesting also called MPC (Membrane Patch ColorimentaryASTM 7843)is recommendated byASTM to performed Regularly test or quarterly at a minimum test.

Varnish Mitigation Technologies

Due to the high profiles and costly eventsassociated with varnish in large frame gasturbines, the market for varnish mitigationhas expended rapidly. Varnish mitigationtechnology can be categories into 3 different areas:

- Low temperature +Depth mediafiltration

- Electrostatic separator

- Chemical filtration by meansof resin exchange technology

Low Temperature Varnish Removal Unit LTVRU-240

In the existing market normally have 3 different types of varnish removaltechnology. Our LT varnish removal unit are make use of low temperaturetechnology to achieve varnish removal. Varnish will dissolve into lubricant fluidgreater than 40'C and if cool down below 40'c, it will gradually precipitate assuspension state in the lubricants fluid. Our LTVRU-240 make use of thisphenomenon to cool down the oil below 40'c by chiller integrated in varnishremoval unit. The cooled lubricant fluid then passing through 2DS depth mediafiltration unit to remove suspension varnish. But specially attention needs to betaken such that the filtration should not allow to increase temperature aftercollecting varnish material in the depth media filter element otherwise varnish willpull out and redissolveinto lubricant fluid again.

| Specification | LTVRU-240 |

| Port Size (inlet/outlet) | G1/2 G1/2 |

| Dimension | 1100×560×1100(D×W×L) |

| Prefilter | fine coarse filter with magnetic stick |

| Voltage | 220Volt / 380Volt |

| PowerConsumption | 6.2KW |

| Weight | 250kg |

| Flow Rate | 240L/Hrs |