Our filter element are patented with specially design in construction.The filter element are made of long fibre cellulous, polypropylene and polyster. Its functioning is based on depth filteration theory. The oil is conducted axially through filter with low pressure and reduced flow rate process. The best filteration performance with pressure controlled between 1-3 bar with a 4 bar maximium. Our filter have high dirt and water absorption capability which is higher than average. The additives of the oil are not influenced after filtration. Our specially design and construction filter element can efficiently remove particles contaminants, oil degradation products, as well as moisture in oil and acidity from oil and fluids, the predicted life time of machines components and oil is expected to be extended by a factor of 2 to 10.

Filter Element Technology and Design

Element change interval

Takinginto consideration the high dirt and water retention capacity, the filter elementchange intervals can be individually determined with according to the contaminationand the volume ofthe oil in the system.

Normally the element change freguency is around 500 operation hours or 6 monthswhichever comes first. On the contrary, in extreme condition, e.g. high quantity ofwater contamination or oil loaded with high amount of sludge, this can cause a filterelement collapse (deformation). in this case, the filter elements have to be changedFurthermore, such a extreme condition the change intervals have to be reduced.

SPECIFICATION OF FILTER ELEMENTS

| Specification | DSDFC | SDFC-Plus |

| Cleanliness calss | ISO 4406:1999 17/15/12 | ISO 4406:1999 17/15/12 |

| Retention | 4000g/800ml | 3000g/600ml |

| HxD(mm) | 262x198 | 200x198 |

| Weight(gram) | 2560g | 1950g |

| Packing | 3 | 3 |

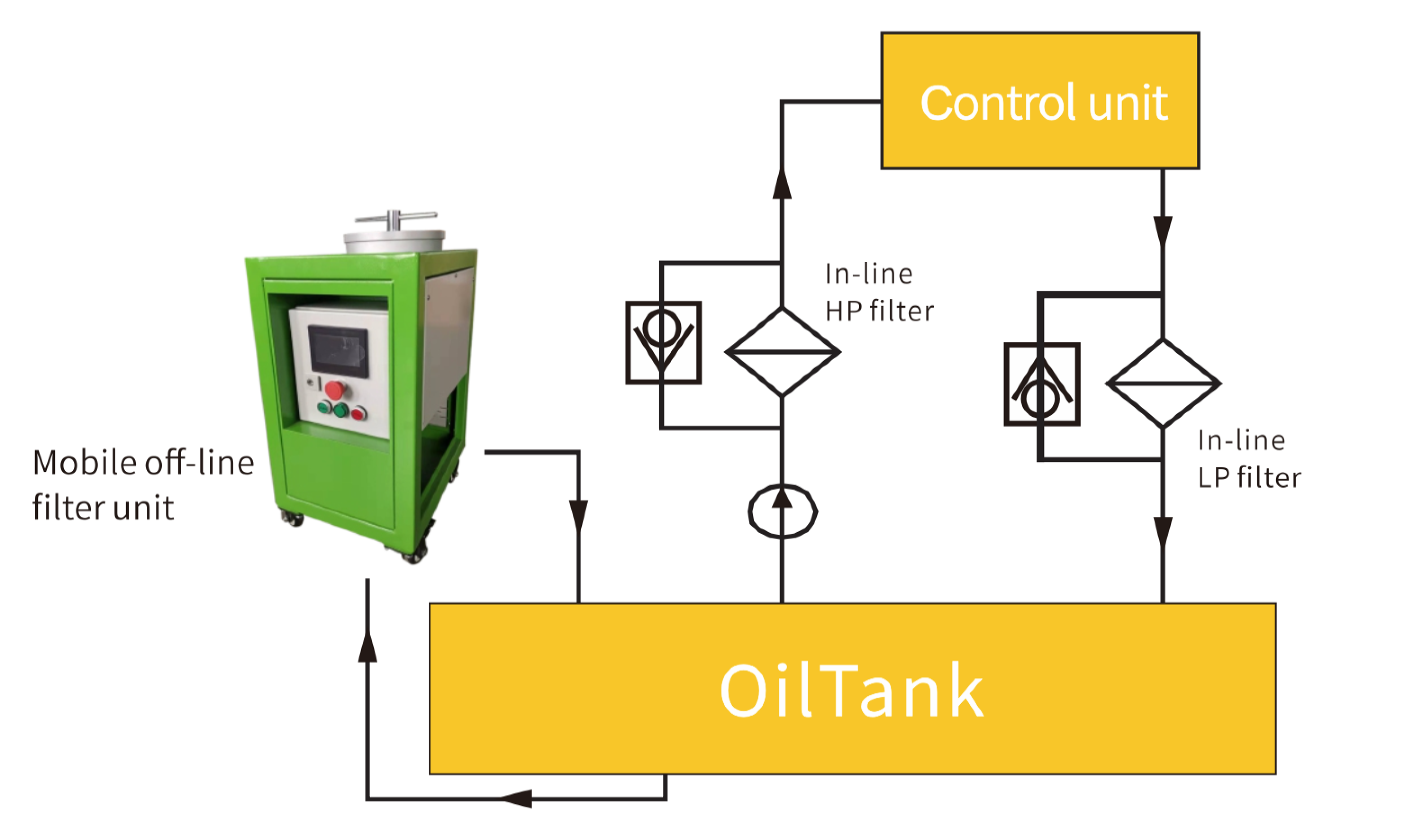

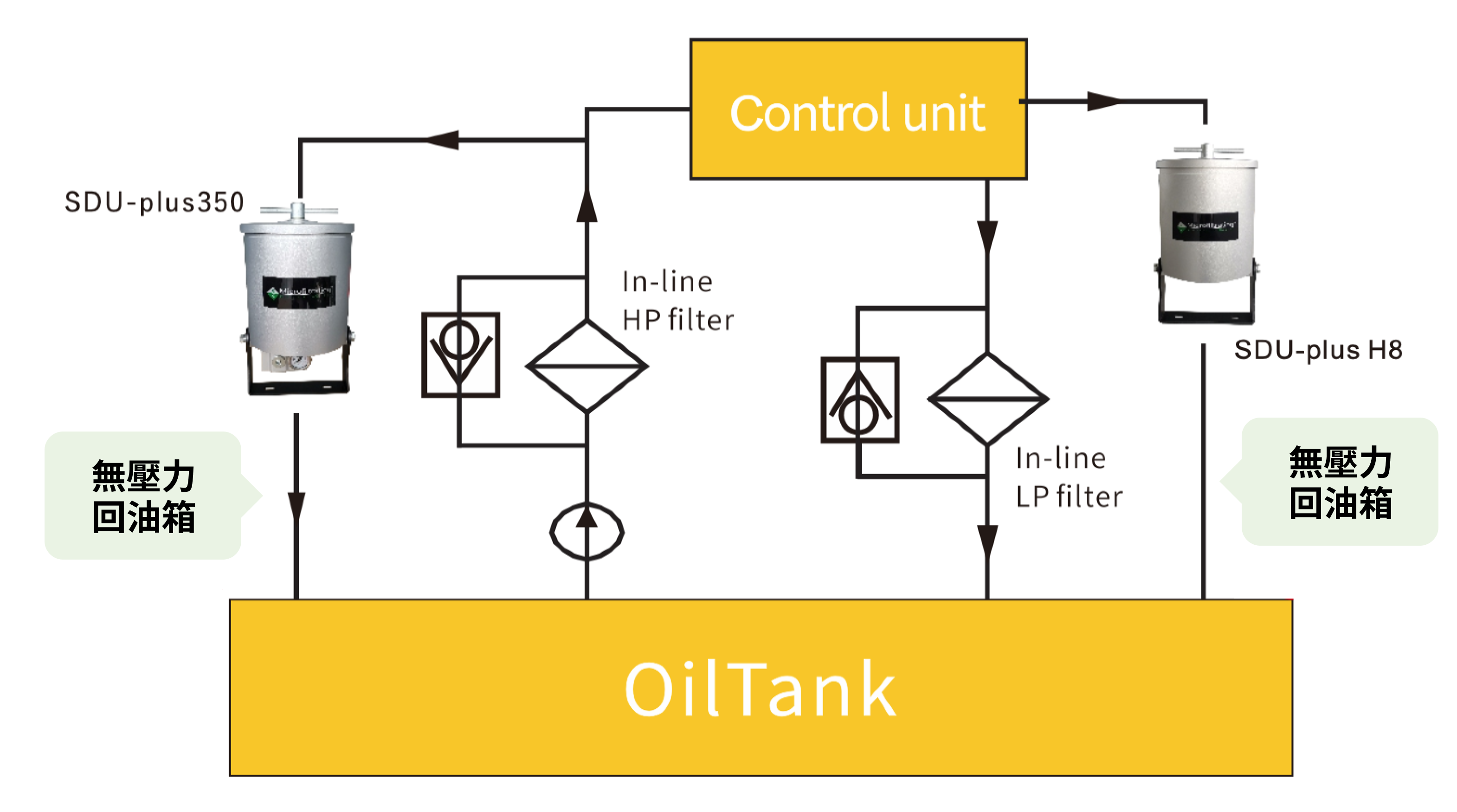

Installation Diagram of Bypass Filter

Installation Diagram of Bypass Filter